Our Product Range

Find the Vinaka product that suits you best

Automotive Paints

There is a shade and style for every vehicle. Find yours from our wide range of automotive coatings.

Auto Refinish Paints

Bring any vehicle back to its original glory and keep it looking flawless with our range of automotive refinishing products.

Electric Vehicle Paints

As the demand for electric vehicles is increasing, it is also raising the need for automotive paint scope.

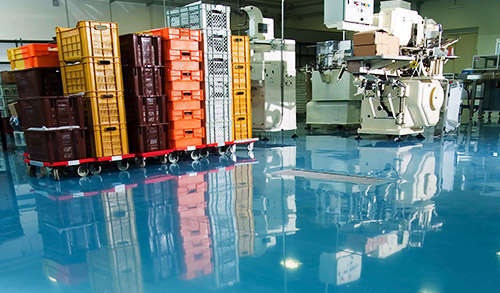

Floor Coatings

We provide complete Floor coating system services meeting customer requirements and also provides eco-friendly system.

General Industrial Coatings

Built an extensive range of expertise by deepening our understanding of diverse industrial sectors.

Powder Coatings

Powder Coatings are a blend of resins, curing agents and pigments, which are melt-mixed and pulverized into finely divided particles.

Decorative Paints

Vinaka’s Paint products are high quality acrylic emulsion paint for exterior & interior walls.

Chemical Industry

We are an innovative chemical supplier specialized in the successful production of super-efficient disinfectants for more than 5+ years in the market.

What Choose Our Services

Design Expert

Environment Freindly

Personalized Service

Health & Safety

Quality Product

Customer Support

Professional Execution

Research & Development

Research & Development

Our holistic approach towards product development can be seen from our well developed research and development wing. It helps us in achieving:

- Technological advancement

- Developing innovative production techniques

- Deliver product changes as per the emerging environment and technology demands

Our Facilities is protected by an extensive fire management system and full back-up generators provide for uninterrupted production in the event of power failures. We have an In-house resin production faciliy to produce acrylic and alykd resins with more than adequate capacity to fulfill of our internal consumption needs, today and in the future. These resin plants allow us to create customized and cost effective resins that in turn allows us to create optimized product formulations and assure batch to batch uniformity.

Production

We have stringent quality control processes that assure a first-time acceptance of ~99%. Our Facilities is protected by an extensive fire management system and full back-up generators provide for uninterrupted production in the event of power failures.

In addition, we have an In-house resin production faciliy to produce acrylic and alykd resins with more than adequate capacity to fulfill of our internal consumption needs, today and in the future. These resin plants allow us to create customized and cost effective resins that in turn allows us to create optimized product formulations and assure batch to batch uniformity.

TESTING & QUALITY ASSURANCE

All raw material is sourced only from known well-established suppliers and undergoes long-term testing prior to use. Every single raw material batch received undergoes specific tests prior to acceptance. We maintain very tight tolerances on all acceptance parameters.

Each production batch undergoes testing by the Production QA group. This includes several tests, based on the chemistry and other requirements of the product being produced. Once these tests are completed the batch is handed over to the Customer Relationship Management QA team.

We are committed to providing the best quality products to our customers. We achieve this by using world class manufacturing practices, by continually improving the effectiveness of the quality management system, by understanding customer requirements and exceeding customer expectations, by complying with applicable statutory and regulatory requirements, by enhancing work environment through 5S practices and continually upgrading the competency of all our employees through training. Our expertise and products make us one of the most desirable paint manufacturers in India.

Frequently Asked Questions

What is the Primary Function of Paints & Coatings

Primary functions of Paint & Coating are for Decoration & Protection.

What are key USP of Vinaka Paints?

Quality Products with Consistent Shades

Tailor made Designing of products understanding end user requirements

Commercially viable products for all Categories- General Purpose / Standard / Premium.

How to select appropriate products for your use?

Product Selection is based on following:

a) Substrates to be painted / coated.

b) Purpose of use – Decorative or protection.

c) Location – interior or exterior.

d) Base of product – Solvent or Water based.

e) Back Bone of product – Epoxy / PU / Acrylated / Resin.

f) Finish – Matt / Glossy / Textured, etc.

Whether one can use paint on rusted surface?

Even minor rust adhering to surface will spoil the paint in long run as rust will propagate through the paint. Hence it is always advisable to make proper surface preparation before painting / coating an substrate / surface. Loose rust particles are removed wire brush / sand paper and then rust adhering / clinging to surface are removed by use of Vinaka’s Advance Rust Treatment products. After Rust Removal area is wiped clean. Then carry on with primer & paint application.

Why Epoxy paints?

Epoxy paints are highly durable paints that can be used for all types of adverse environments. They are highly anticorrosive and give a very aesthetic appeal to substrates.

Can PU paints replace Epoxy paints?

Yes PU paints are equally high standard as compared to Epoxy paints. In some ways it is better as they offer additional qualities like better sheen, fast curing, flexible UV resistance coating.